FAT-500 First Article Tester will automatically inspect the first PCBA board by integrating a BOM (Bill of Materials), scanning high definition images, and quickly making accurate component inspection. It automatically analyzes and generates a first article inspection report. This will enhance production efficiency and capacity while strengthening quality control.

Feature

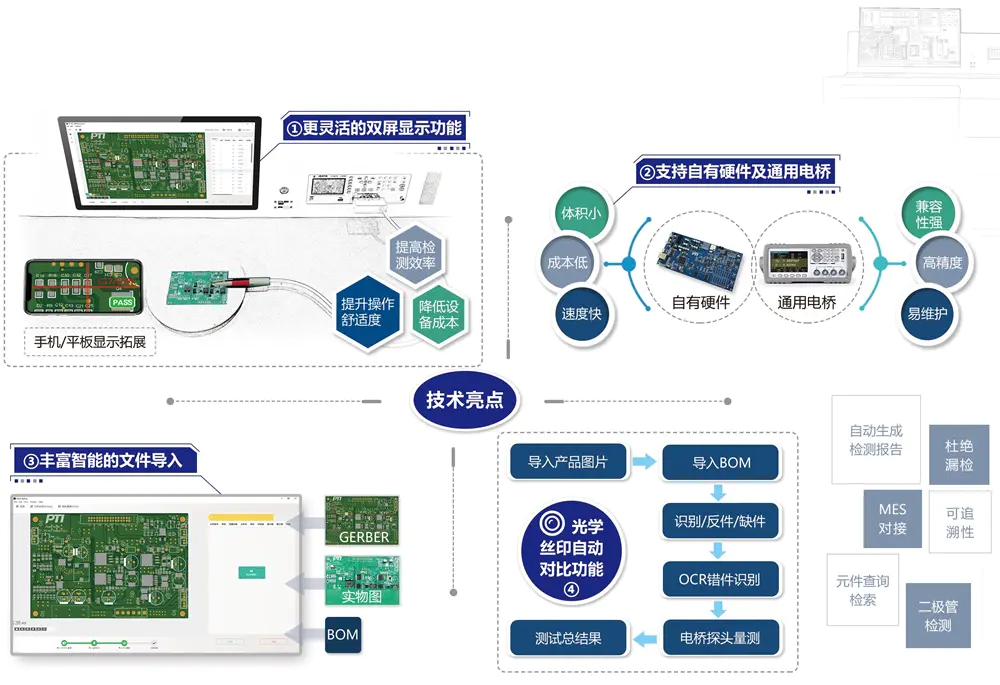

1. For IC Chip (Integrated Circuit), diode, triode and resistor symbols, capacitance and electronic components, the system can use automated optical inspection to carry out automatic inspections. The machine supports multi-point inspection for identical components, while the programming process is simple and fast, only need to be created once and can be used multiple times.

2. Custom system software features strong and flexible BOM analytical capability, enables it to deal with different types of BOM and analysis techniques ensuring its compatibility with multiple BOM types.

3. Use SQL Server database, it’s suitable for storing huge data, enabling multiple servers and centralized data management while facilitating integration with existing ERP or MES systems through the storage process.

4. The system receives high definition images from scanners and the testing data of the terminal block then automatically determines whether it’s PASS or FAIL, it can be manually determined on a computer by staff.

5. Proprietary software has unique algorithms that automatically switch modes, reducing manual intervention and providing high-speed testing results.

6. Support double sided data import

7. Automatically create reports after finishing the test, export Excel/PDF format to meet the customer's file sharing requirements.

8. Flexible access permission (divided into manager, engineer, inspector account) to prevent unauthorized modifications or user errors.